TECHNOLOGY R & D

technology R & D

- Categories:R & D manufacturing

- Time of issue:2018-12-17 00:00:00

- Views:0

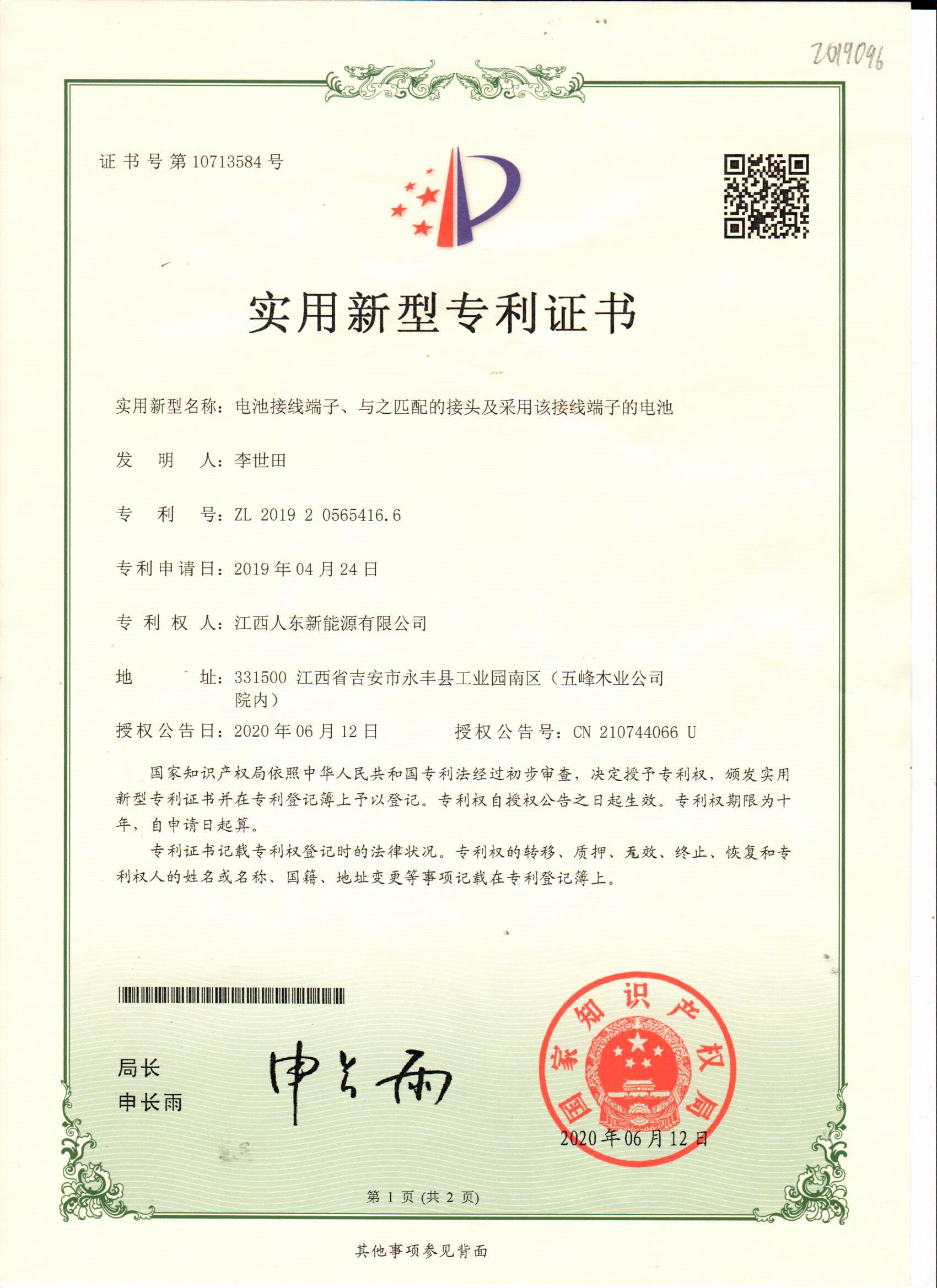

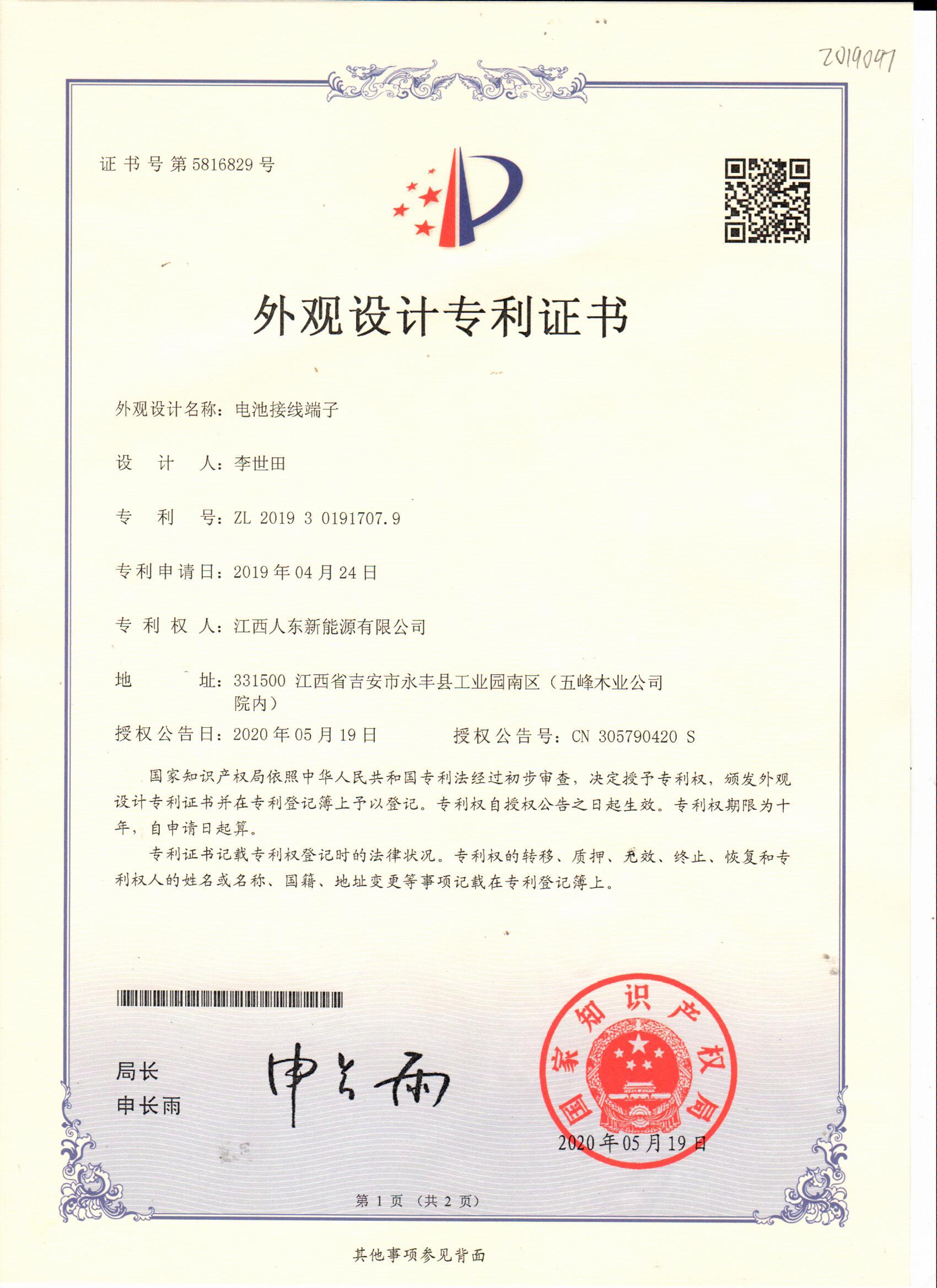

Jiangxi Rendong New Energy Co., Ltd. is a comprehensive enterprise with more than 15 years of battery production, sales and research and development, of which professional technical personnel and management personnel account for 60% of the company's total staff. The company always regards "exceeding customer expectations" as the guiding principle of the company's product quality, and "safety responsibility is the day" as the inspection standard of the company's product reliability. The company has always attached great importance to the improvement of process technology and the research and development of new products. It has established strategic cooperative relations with universities and research institutions at home and abroad for a long time to jointly develop scientific research and promote the transformation of technological achievements. It has a number of independent research and development technologies. And national patents to ensure that the product process technology is always in the international lead.

Core technical team:

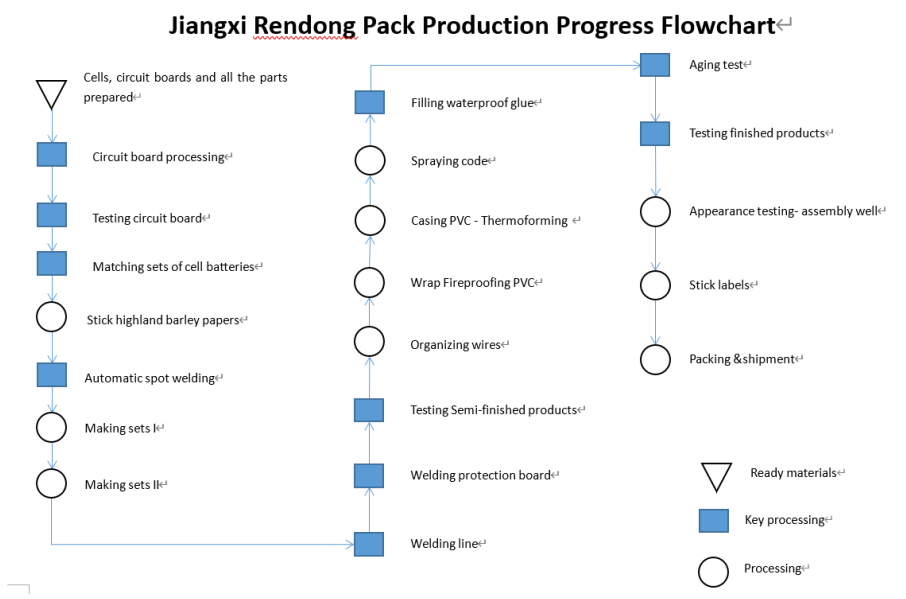

R&D Department: Responsible for new products, new process development, PACK system optimization and upgrading, new product reliability testing, establishment of intelligent manufacturing system, and planning of the company's long-term and short-term technical goals and technical routes.

Technology Department: Responsible for the company's process control and process optimization, improve product quality and product reliability, and reduce product production costs.

Production Department: Responsible for the formulation of production plans and the scheduling of production materials, and perform production operations in accordance with the technical requirements provided by the technical department, organize the statistics and production tracking of various parameters in the production process, collect, sort, and analyze various production-related items Basic data provide a basis for production decision-making and process optimization, and organize training and assessment of workshop personnel.

Quality Department: Responsible for the quality inspection of the company's products and the reliability test of the final product, including IQC inspection of raw material cells, BMS and battery pack IPQC inspection in the production process, and FQC and OQC inspection of the final product. Provide guidance for the company's product optimization and provide data support for after-sales work.

Production equipment

Main production and testing equipment: automatic cell sorting machine, high-power spot welding machine, automatic spot welding machine, laser welding machine, BMS testing equipment, thermal film shrinking furnace, comprehensive testing equipment for lithium battery packs, battery aging testing equipment, large Current charging/discharging equipment, laser typewriter, etc.

Main test items for lithium battery packs:

1. Visual inspection

2. Electrochemical performance test: overcharge protection test, over discharge protection test, over current protection test, short circuit protection test, life cycle test, capacity test, open circuit voltage/internal resistance test.

3. Environmental performance test: high temperature test, low temperature test, drop test, vibration test, etc.

4. Safety performance test: overcharge test, overcurrent test, short circuit test, etc.

QR code

Mobile site

rendong

Online message

Copyright © Jiangxi Rendong New Energy Co., Ltd. Gan ICP No. 20007021-2 www.300.cn